I’m just coming off of an awesome Piedmont trip with low IMC, DCA airspace, and excellent approach opportunities in the DASH. I am better able to take full advantage of the CRM coming my way; these Captain’s are really good under pressure.

I’m just coming off of an awesome Piedmont trip with low IMC, DCA airspace, and excellent approach opportunities in the DASH. I am better able to take full advantage of the CRM coming my way; these Captain’s are really good under pressure.

I realized toward the end of that trip that the weather wasn’t going to improve for the planned flight test of my PA30 on the 3rd. I emailed both mechanics that I’d have to push the test a day due to weather. Each of them got back to me within just a few hours. This kind of contact and response in support of safe decisions is appreciated customer service.

The paint project has been dragging on a bit, to say the least. The repairs and paint look amazing, but getting the re-skinned control services trimmed just right is proving challenging for the shops.  Multiple flight tests adjusting ailerons and flaps yield inconsistent results and never get me back to straight and level flight. I came in fast and true in this bird, and will only be leaving the same way. New paint or not.

Multiple flight tests adjusting ailerons and flaps yield inconsistent results and never get me back to straight and level flight. I came in fast and true in this bird, and will only be leaving the same way. New paint or not.

The issues that remain are most noticeable in cruise and at speed. The yoke position is canting to the right on it’s own, as it would if I was commanding a right bank. The airplane banks a bit left as a result of the significant adjustments in place with hands off – and the right aileron appears to ride high. Totally uncool, but the only way it will be manageable in level cruise.

I’ve talked about this several times already, but fully expect that today will be the day we get this right. Yes – I’ve said this before. One more flight up there; resetting of the aileron trim tabs and rod lengths to spec (taking out the latest adjustments); and a tweaking of the flap positions in neutral – the move that seemed to show positive correction on the last mission.

I am convinced at this point that the flaps are the key to getting back to fast and true, and it is hard to get that out of my head. I really want this done before real winter sets in and getting up there on my schedule becomes a royal pain in the empennage.

Now it is the morning of the 4th, and the weather was clear and cold. Frost is a concern, but I had no intention of spraying anything on my fresh paint. Benign de-ice or not. I plan to pull the airplane out and let the the rising sun do it’s thing.

Leaving my Smyrna home at 6am and heading for Georgetown, I arrive at the field to find both entrances blocked. Construction crews doing something on the field were conveniently blocking both gates to the airport, so I waited for 15 minutes or so. The sun was coming up and it was starting to warm up slowly, so that made waiting easier.

I dropped of the power-tow at it’s new home in Georgetown, and used it to pull the airplane out. I’d fueled it after the last trip, so the pre-flight went smoothly, and the flight up was uneventful. Slight left bank with these controls and a limited ground speed due to a strong headwind. I floated a bit on the landing, but it worked out. I was on the field at Smoketown around 8:30am and ready to get this done.

Flight #3.1 – Dennis took the aileron adjustments out by changing rod lengths and resetting trim tabs before I performed a solo baseline test flight. I thought this was a waste, but really needed to pipe down and let them do their thing. The takeoff and climb-out were predictable. Pitching over we were right back where we started – the B#@ch wanted to roll me over. To the right again this time; right aileron riding high and yoke indicating a right bank. Back to the field and land for another discussion. The airplane is not safe to fly in cruise like this. Losing the right engine in cruise would leave me with diminished control authority and an impressive roll rate.

Flight #3.2 – I pushed my flap idea again, but both mechanics discounted it. They wanted to try another aileron adjustment, so I relented – again. I thought this too was a waste, but I had every intention of building a plan for them out of these tests – or taking it elsewhere.

One more aileron adjustment and off I go. Seemingly predictable results and still with no clear plan. I don’t share my thoughts but am seriously considering taking the airplane home to my own mechanic. My patience is waning and I think I am more right than they are. In the end, I am not, so read on.

Risk Management

Throughout all of this experience, I’ve repeatedly briefed on avoiding complacency for both mechanics and pilots (me). I made sure to insist on having one mechanic do the work, while another verifies safeties are in place and controls are secure before I fly. In fairness, they were doing this already on their own before I started paying attention to what everyone was doing, but now I was directly engaged. I checked the controls full range on each flight – and repeated this while the flaps were in motion both up and down. I did not want to freakin’ die because of an over-sight.

Doing the same flights over an over with the challenges I was facing alone were giving me increasing concerns. The field is only 2400′ long, was previously shorter than my personal minimums, and now I’m flying in and out several times a day in an airplane with control issues. I talked everyone through this on the hangar floor, and emphasized the need to get this done before I had an emergency or did a gear up on the field. I’m tired and frustrated; everyone working on the airplane was tired and frustrated; and we had to look out for each other.

Flight #3.3 – At this point I insisted on getting an opinion outside of the current team. Dennis brought another mechanic, Mike, into the discussion. I offered to get my mechanic in Georgetown on the phone, but that didn’t get any traction. Mike didn’t see anything wrong in our thinking, so Dennis suggested the guys at WEBCO. That sounded like a good idea, so he made the call.

As Dennis tells it, the gentlemen at WEBCO chuckled when he heard of our plight, and suggested that the aileron tabs were hyper-sensitive. We should try them again. Total bullshit in this scenario – I knew from flying the various settings that we were well outside of the range of mechanical trim tabs with this issue. The reason I agreed to another flight was what else he had to say.

Now we had a plan. If we still had a roll problem with the symptoms described after the rigging and aileron trim tabs were set as recommended, we needed to replace the ailerons. One or both might have been warped in the process of re-skinning.

Dennis and his crew made the changes and I took runway 28 for departure once more. by the time I reached pattern altitude, I’d had enough of fighting to keep it level. I returned for a landing completely frustrated and out of patience.

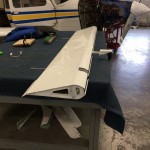

Removing and inspecting ailerons

Somehow Dennis knew the left aileron was the culprit. This tells me he was aware of the warping, but that the tolerance was acceptable in his mind. In any other airplane he would probably have been correct to assume this, but I’d think it would have cost the unknowing owner a few knots of top speed. Let’s move on.

Somehow Dennis knew the left aileron was the culprit. This tells me he was aware of the warping, but that the tolerance was acceptable in his mind. In any other airplane he would probably have been correct to assume this, but I’d think it would have cost the unknowing owner a few knots of top speed. Let’s move on.

Both ailerons are removed and measured, and indeed, the left aileron is warped by 1/4″. WEBCO recommends that this be the maximum tolerance, and notes that even less may drive you crazy trying to use a warped aileron. Better to replace it.

The right aileron is straight and true, so a left aileron from  a single Comanche that is there being painted is measured. It is also straight and true, so it is installed on my airplane for a test flight. If this doesn’t do it – I’m going to talk with the shops about getting an opinion from my own mechanic, and will do that regardless to end this cycle.

a single Comanche that is there being painted is measured. It is also straight and true, so it is installed on my airplane for a test flight. If this doesn’t do it – I’m going to talk with the shops about getting an opinion from my own mechanic, and will do that regardless to end this cycle.

Executing the WEBCO plan

It will take them an hour to get these ailerons off and on, and I don’t want to rush anyone. I remind them all of my safety concerns and that my ass is on the line here. I opt to walk to find lunch and give them that uninterrupted hour. They offer a ride, but I decline in favor of using the cool air to consider my options and review the upcoming flight.

Outstanding thin crust pizza at Gionelli’s near the field improves my mood. I mull over the explanation from WEBCO and the shops that the flaps are not the issue, and believe them.

Returning to the shop, I see four mechanics working on the airplane and cross checking each other’s work. I am walked through all the changes and inspect my ‘new’ left aileron. The airplane is pulled out and I taxi out for a test flight with someone else’s aileron.

Flight #3.4 – Departing runway 28 uphill again, I notice no banking tendency on climb out. I reflect on the fact that the mechanical tabs on the ailerons have been moved all over the place; the odds of getting them this centered all of the sudden magically are remote; and the assertion that these are hyper-sensitive has no basis. But I digress.

Left turn to the south and level off at 1700′. There is a helicopter in the distance, but it is cold and I accelerate toward him rapidly. Banking left to the east along the ridge, I accelerate to cruise and note no bank. Straight and true and she keeps building speed – what a rocket ship! My baby is back, although with an ugly paint job on the left aileron.

There is an experimental I’ve been listening to, inbound to Smoketown from the east. He has radio skills and I can tell he knows what he is doing.

I’m really excited now that the problem has been identified, and relief washes over me. I feel the need to do something stupid. I talk with the experimental to get my eyes on him and tell him I’m planning on a low-pass. He lands and gives me the all clear as I make an extended downwind turn to left base. I tell myself this is a good way to build speed and test the ‘new’ aileron. I turn final, keep it clean, and push the nose over.

I keep some power in and watch the limits. Gear and flaps are up, but I see an Extra (the experimental airplane) on the departure end. His is stationary and in a position to observe the show head-on; no doubt planning to scoot out of there if things got hairy. I verify it is him, and that he feels ok where he is. He does and encourages me.

Dropping over the power lines I goose the power and flashed over the field well ahead of the sound of straining propellers. Just shy of my audience, I pull just hard enough into a climbing left chandelle. I find myself on a left downwind with the power pulled back in just a heartbeat or two. He airs his appreciation and I feel wonderful.

Gear down – flaps down – taxi in and shut down. Time to take the borrowed aileron off and re-install my warped one. The odd adjustments were made again to make it flyable, and Dennis promised to build or buy me a new left aileron. They made a paint pattern right there, so I will hopefully be able to fly up one more – final – time for a few test flights with the new one.

Later that night I told my wife about the low pass. She was not impressed, and reminded me that I would have criticized this decision in others. I had no argument. Bad call on my part, but it ended well.

One more session to go.

Fly safely – do as I say, not as I (sometimes) do.