This blog and others like it represent the updates I’ve been sending to my teammates as I go through the training required to get a type rating in the Gulfstream G280 corporate jet. These are intended to help them understand how the training is structured, and be even more prepared than I was.

11 Days before I go home, and this is the last ground school we’ll have. The session is completed in the simulator, but not on motion. I cannot wait to go home.

It is laundry night tonight, and I’ll try once more to get to WhataBurger to try that out. Paul J is a friend of mine with family down here, and he always FP posts himself eating there. I thought I’d give it a try. Didn’t make it last night since I went out with the 2 instructors and my partner for a beer or three. That was a good get-to-know-you session. I am getting a sense that the instructors down here have horrible schedules and need some relief.

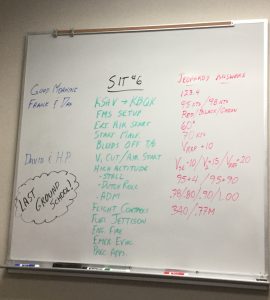

What follows is a description of the SIT Session for today. It was an introduction to checklists for both emergencies and alternate normals. Don’t do anything without a check-list – even a fire. Abnormal starts; aileron jams; elevator jams; V1 cuts (I didn’t get one of those yet).

My weak area was call outs on take-off and landing. I have too many of them and they are non-standard when I’m in the right seat. I’ll correct that for today (airspeed alive; power set; 80 kts; v1; rotate; Vse).

One instructor asked us questions to prepare us for the oral. I knew most but not all of them. It was enough to send me back to the walk-around to remember where the various doors and vents are.

We learned to include the destination airport not only as the arrival airport, but also as a waypoint in the flight plan. It helps the computer predict fuel at the destination.

From this point forward I have summarized my notes thus far for my teammates preparing to train. I doubt they’ll be of interest to the average aviator. I’m first in the left seat today, and actually looking forward to it.

Questions of the day:

123.4: Oxygen. 123.4 lbs of O2 at 1850 psi

123.4: Oxygen. 123.4 lbs of O2 at 1850 psi- 95 kts / 98 kts: Vmcg and Vmca or Vmcl

- Red/Black/Green: Emer Bus or Stdby Bus; Distribution; Main

- 60 deg: nosewheel steering limit

- 70 kts: below this speed on a rejected takeoff you get medium auto-brakes. It is the only call-out on landing

- Vref + 10: Circling speed – fully configured two engines

- Vref + 5: SE approach speed with flaps 20 (not asked, but I added it anyway

- Vse-10/V2+15/Vref+20: Min Flap Retract speed in normal, SE eng failure, and go around mode.

- 95+4 / 95+90: APU at 95% will get you a generator after 4 seconds and bleeds at 90 seconds

- 0.78/0.80/0.90/1.00: Underspeed CAS; PLI Angry eyebrow symbol; Stick Shaker; Stick pusher

- 340/0.77: speed limit with MAC Trim InOp

Questions from the previous day included:

- 20a / 8a: Battery charge limits. You can’t takeoff with more than 20a if the APU in available (it can be off but available). You can’t take-off with more than 8a if the APU is InOp or unavailable.

- 2600-3000: Required Gear Bottle Nitrogen Charge

- FL 390 / 10: Hydraulic EMP Limited above FL390 to 10 minutes

- 3 deg: Fuel temp limit at the filter

- 15% N2: Causes APR to activate

- 1300 psi: EMP turns on if armed. If accumulators are lower than this at the start, turn on EMP to charge.

- -1/2.6: G load limit flaps up

- 0/2: G load limit flaps down

- Emergency gear down at 175; normal gear down at 195 kts

- FACE: order of fuel burn. Forward tank, aft, center, everything else

- 16 fuel nozzles and only 4 used to start

- 1 ignitor is used to start, but 2 are used for starting in flight

- 7240 max continuous thrust; 7624 max take-off and max apr as well

- You can start APU in the air up to FL350 and operate it up to FL400

- Fire bottles are 600psi in the tail

Initializing the CDU

- Pos Init

- Check database

- Perf Init

- Take-off Init

- Departure and Arrival data

- Note the CG is going to be 39 or 40, and your perf calculations would have that

Some other things that came up along the way:

- DDA: Derived Decision Altitude. If you are using automation to level off at an MDA, add 70′ to the MDA.

- When flying a programmed glide path on a non-precision approach, dial the dirt (set 0 in the altitude selector. This will take you all the way to MDA +70 (DDA) without leveling off. At DDA you go missed by selecting TOGA and PF commanding ‘Set ref+30’ and ‘Set Missed Approach’. The later means altitude as well and ensuring the flight path is set up.

- Pavement weights: PCN / ACN: This has to do with the amount of weight an airport pavement can take. Not all airports report a PCN, but you can find it in the AFD. PCN is for the airport itself. ACN is for the aircraft. If ACN is less than PCN, you are good.

- TORA/TODA/ASDA/LDA all in the AFD. Takeoff runway available, Takeoff Distance Available, Accelerate Stop Distance Available, and Landing Distance available.

- Sims are based on Specific Issue #1 aircraft, and are updated to continue matching those aircraft.

- This aircraft uses NO BLUE WATER and cannot be serviced with it. Also DO NOT use distilled water since the level sensors won’t see it. The later means that computers see no water and won’t work. You’d have to drain out the distilled water and refill with tap. Water must be drained before leaving the airplane in freezing conditions.

- If you need WAI (wing anti-ice), the wing temps must be at 130 deg for T/O. WAI needs to be on prior to entering icing conditions

- 26000′ limit for single source bleed operation

- 185 kts min hold in icing

- 30 second limit for testing probes on the ground

- Static ports are not heated – EVER. They are in an area that won’t ice.

- Turn on anti-ice below 10 deg with visible moisture

- Nacelle bleeds fail open

- V-speeds will not post if 10 kt tailwind limit is predicted on the landing runway

- SE ILS on autopilot is approved

- At 30,000#, the best L/D is 170kts. It changes 3 kts per 1000′ (faster I think)

- Nose temp fans come on at 113 deg and you get a CAS message at 140

- Engine starts need 32psi min

- Temperature set points for bleed air: 400 with no WAI; 450 with WAI; and 500 for SE operations

- There are 3 general aviation digital controllers that make up the Air Management System Controller

- Turns are automatically half bank over FL290

- Tire Speeds: 225 mph/195 kts mains; 210mph/182 kts nose

Fly safe

Frank